Assembly of optical systems and optical bonding

One of the most delicate phases in the realization of precision optical systems concerns the assembly activities of the various optical, mechanical and / or electronic components that make up the system.

To ensure proper operation, a correct alignment of all components is required in a controlled atmosphere laboratory with particularly pure air. Lobre is equipped with two ISO 7 class clean rooms and specific blowing hoods to ensure the ideal environment for the assembly of optical components and systems.

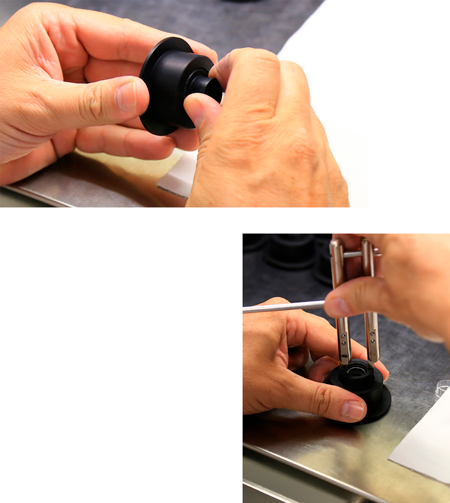

Also the bonding activities of two or more lenses that make up the optical groups (achromatic lenses, triplets) requires extreme precision and a particular knowledge of the various optical bonding methods and the availability of particularly sophisticated instrumentation such as the Trioptics instrumentation used in Lobre.

Lobre is a real one-stop-shop and is fully vertically integrated: all activities, from the production of optical and mechanical components, the coating to the assembly, can be carried out internally. Our experience as a manufacturer of precision optical components allows our experts to handle all components with the necessary care without involving other realities, therefore avoiding any problems of damage to often very delicate optical components. It is possible to set up a dedicated assembly line in an ISO 7 clean room for our customers.